Ai Digital Biology

Touchlight Genetics: Synthesizing the DNA of the Future

Sep 27, 2018

DNA is an amazing substance with incredible technological potential. It may be the building block of life, but in the age of biotechnology, it can be harnessed to do even more. DNA can store data, power nano-electronics, and be used in computation, metabolic engineering, and sensors — the list goes on.Still, one of the most exciting uses of DNA is in therapeutics. It can reduce time constraints, improve efficacy, and ramp up distribution — but producing DNA at this sort of scale is no small feat. A DNA vaccine for an outbreak like Ebola would require multiple kilograms of DNA. When produced by standard plasmid DNA fermentation, this requires thousands of liters of live bacterial cultures, and expensive, large-scale harvesting technologies. Plasmid DNA fermentation is an invaluable tool in DNA research, but when it comes to producing high-quality therapies on a global industrial scale, a more powerful process is needed.Enter Touchlight Genetics, the London-based winner of the 2016 Best Emerging UK Synthetic Biotech Company award. Founded by CEO Jonny Ohlson in 2008, Touchlight is revolutionizing DNA-based therapeutics and technologies by removing the limitations of large-scale DNA supply.

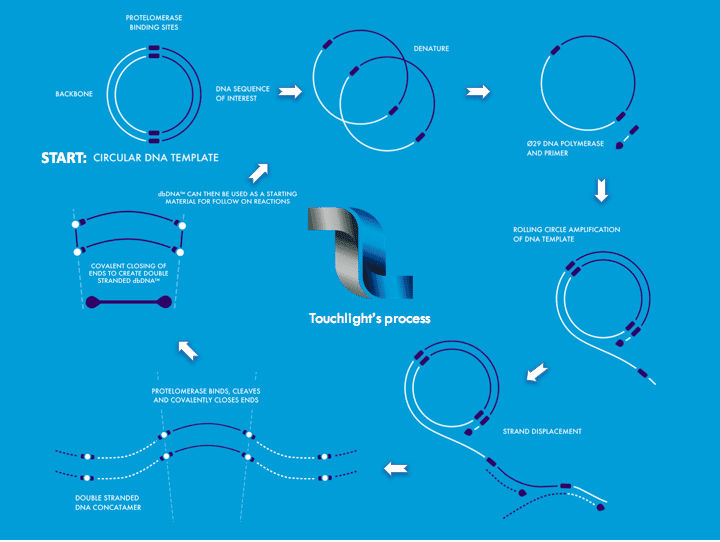

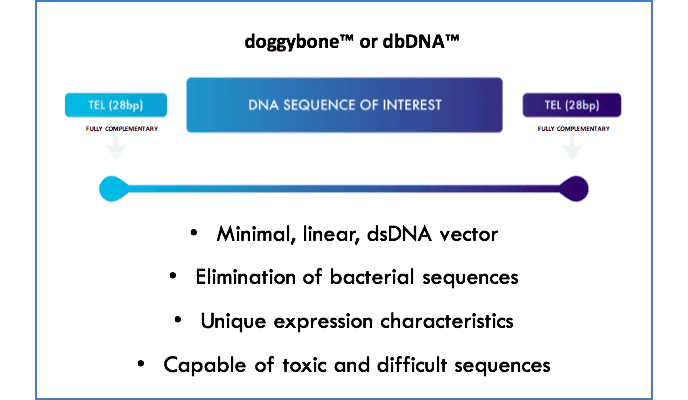

Touchlight’s doggybone dbDNA production process.Touchlight’s product, doggybone DNA (or DbDNATM), is a linear, double-stranded DNA construct produced by a novel enzymatic process in a cell-free environment. Starting from a verified circular DNA template, the template is denatured, the circle is amplified using a DNA polymerase and a specific primer, and the new double-stranded sequence is cut out by a protelomerase, which covalently closes the ends to create the double-stranded “doggybone” DNA product.DbDNATM is unique in 3 ways: it completely eliminates extraneous bacterial sequences, it can be designed to incorporate even sequences that are toxic or low-yield in E.Coli cells, and it maintains high fidelity even at a large scale.

Schematic of Touchlight’s doggybone DNADbDNATM is truly ‘tailor-made’, says Milsom, and unwanted bacterial sequences — a common hurdle for advanced and genetic medicines — are eliminated. In the context of therapeutics, this reduces unwanted immune effects, not to mention the risk of including antibiotic resistance genes that come with fermented DNA. Removing these sequences also changes how the DNA behaves, making it more efficient as a therapeutic.The cell-free production allows for sequences too large or difficult for many conventional methods to handle. Without having to worry about low-yielding, toxic, or regulatory gene products, the door is opened to a whole new set of gene sequences, which can now be explored as product opportunities. Touchlight recently made a >40,000 base-pair DbDNATM; the upper limit for a sequence in a standard cell-based plasmid hovers around 15,000 base pairs.The process is also highly scalable. In a lab, high-yield DNA production is often measured in milligrams; industrial organizations like Touchlight can churn out quality DNA on a multi-gram scale, in a cost effective way, and in just a couple of weeks.For Touchlight, revolutionizing DNA amplification is a means to an end. They are motivated, ultimately, by the customers who will benefit from this highly scalable and versatile technology. “Getting a therapeutic product into the clinic is certainly a huge goal for Touchlight,” Milsom says. “In the industrial space, we want to see DNA in a product on the shelf.”Convincing consumers is always a challenge, but there are numerous areas to pursue. Consider the “cold chain” system for vaccine storage and transportation: to keep vaccines potent, they must be kept at specific optimal temperatures from start to finish, all the way down the pipeline. This is often extremely difficult, especially in developing countries, which have the highest demand for vaccines but often have limited resources and equipment. For instance, a WHO inventory analysis in 2003 found that much of the cold chain equipment in Ethiopia was outdated and in dire need of repairs — and only two-thirds of it was functional at all.Improved DNA vaccines, however, would be a boon to vaccine production; because DNA is quite stable at room temperature, the pressure to stick to the cold chain system is massively reduced compared to other vaccine platforms. Milsom hopes that DbDNATM could play an important role in the expansion of DNA vaccines.

The cold storage conditions required for most vaccines make them difficult to use in the areas where they are most needed; Touchlight hopes to solve this problem through their DbDNATM. Photo by John Keith via Wikimedia Commons.But the possibilities aren’t limited to medicine. Touchlight is working with collaborators to use dbDNA™ as a starting template for the large-scale production of compound semiconductor nanowires. These materials have high-value applications such as electrical pollutant sensors, quantum dots, and anti-counterfeit inks — but manufacturing them is typically complicated and expensive. A double-stranded DNA backbone, however, is a low-cost scaffold for metal ions — an easy way to produce printable compound semiconductor materials.“We are joining forces with people who have a vision for DNA as a fundamental material of the future,” says Touchlight’s DNA Nanotechnology Lead, Sarah Milsom.Touchlight is also working with the University of Utah to use DbDNATM in the production of powerful DNA-based biofuel cells, or biobatteries. These are powered by enzymes, which break down organic compounds like glucose for fuel. DNA hydrogels are an excellent scaffold for enzymes, and because they are totally biocompatible, they are a good candidate for implantable bio-harvesting products. The University of Utah’s battery offers dramatic improvements in battery capacity, but its commercial advancement depends on high quality DNA production on a massive scale. That’s where Touchlight comes in.In the age of biotech, DNA is becoming a major commodity, and one that Touchlight hopes to provide. “We are going after genes and genetic medicines that were previously unaddressable, as well as whole new applications previously thought unviable,” Sarah says. “DbDNATM is everything you want from DNA, but nothing you don’t.”