Ai Digital Biology

Synthace Integrates Powerful Automation Equipment with its High-Level Language for Biological Research

Jun 24, 2015

At the O’Reilly Solid conference in San Francisco, a meeting dedicated to the new hardware movement and the Internet of Things, Synthace will be announcing today a partnership to integrate its Antha language with liquid handling equipment from Gilson and CyBio Northern Europe. Sean Ward, CTO of Synthace, will also be announcing a sign-up program for a closed-beta release of the Antha language that will become available in July. This release will include an automated DNA construct assembly protocol that will enable researchers to generate 24 constructs in under an hour using a Gilson Pipetmax®."We are delighted to be working with these leading equipment providers to bring the Internet of Things to academic, clinical and industrial laboratories through integration with our Antha platform. Improving reproducibility and productivity across biological R&D will be absolutely reliant on establishing this type of connectivity", said Sean Ward, CTO of Synthace.

Productivity Requires Reproducibility

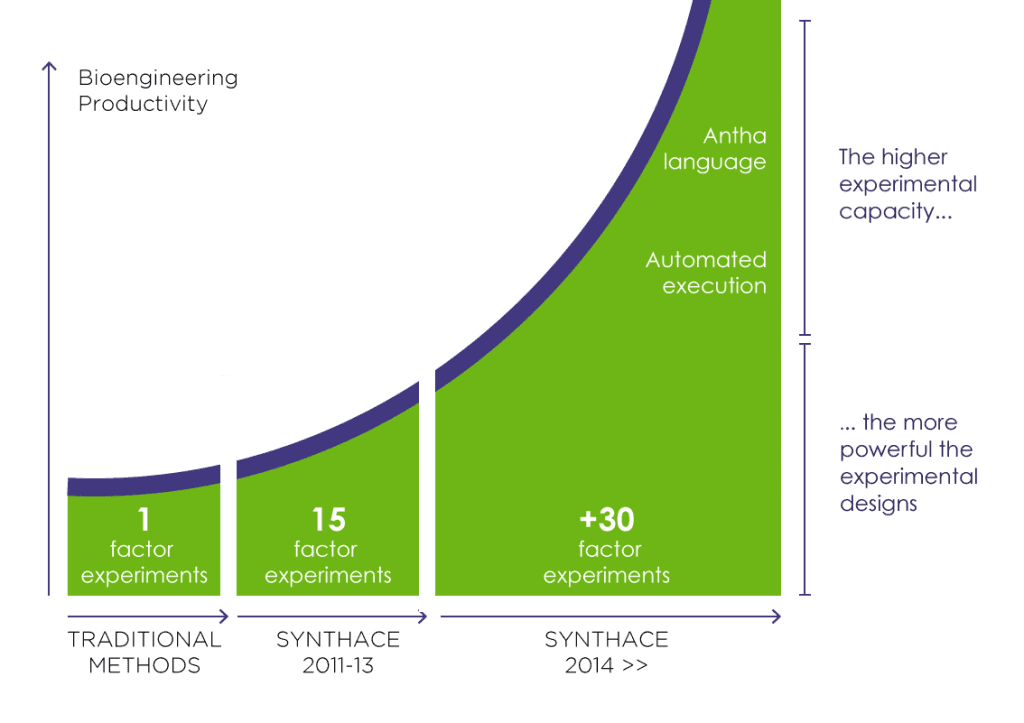

Synthace has invested heavily in liquid handling automation and the development of Antha, a high level, open source language for biology that allows users to develop, execute, and analyze biological experiments more efficiently.Such a programming language for biological experiments is important for scientists for many reasons. Mainly because much of a scientist's’ day is spent performing repetitive, time-consuming tasks that can now easily be automated. An intuitive, power program like Antha will allow scientists to focus their time on planning experiments and analyzing data instead of performing rote work that a robot could do.

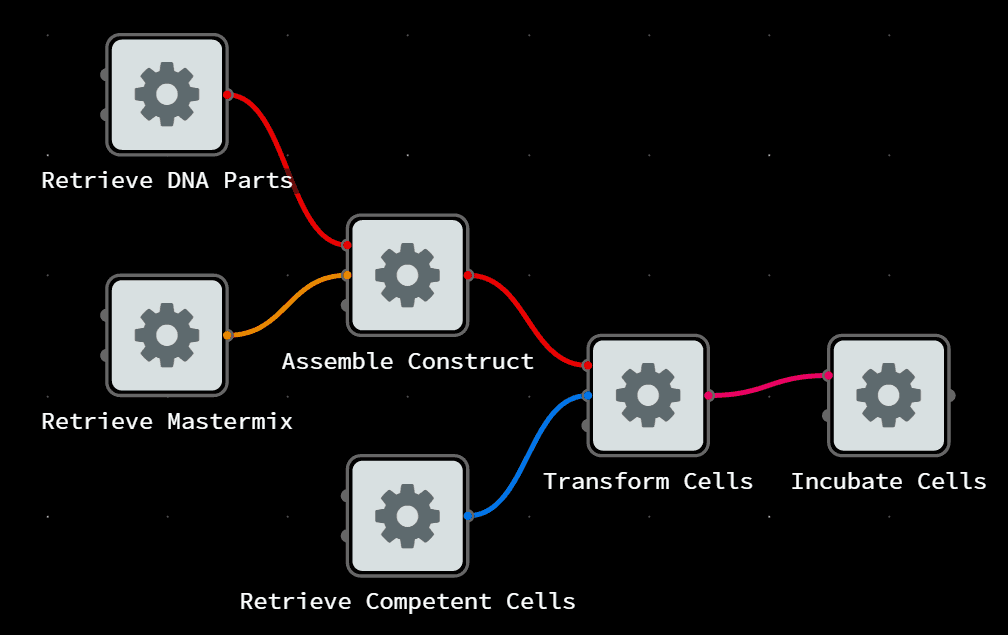

Furthermore, lack of reproducibility is a huge problem in biological research. For instance, Amgen reported that they could only reproduce findings in 11% of the 53 published papers they surveyed. This very serious inconsistency can largely be attributed to small changes in the experimental protocol introduced by human error and because scientists don’t record every aspect of the process in the final paper.According to Roger Peng, Associate Professor of Biostatistics at Johns Hopkins Bloomberg School of Public Health, some of the problems at the heart of the reproducibility crisis have been “a shortage of software to reproducibly perform and communicate data analyses” as well as unavailability of published data “for inspection and reanalysis”.Performing the experiments in a robotic laboratory that automates the collection of data, and records and describes the process completely, eliminates many variables and sources of error. Not to mention, that through automation, scientists can perform much more complex and large-scale experiments in a shorter amount of time than traditional methods.Antha was designed to make reproducible and scalable workflows by stacking elements such as genetic elements (e.g. a single gene, or a whole plasmid) and experimental procedures (e.g. DNA assembly, enzyme assays) so that they can easily be exchanged and rearranged. Just as critical, the language standardizes and fully tracks the experimental procedure allowing for complete documentation and reproducibility. Therefore, once elements and workflows are designed and tested, the scientist can download the protocol and include it in a research article.

An intuitive Antha workflow.

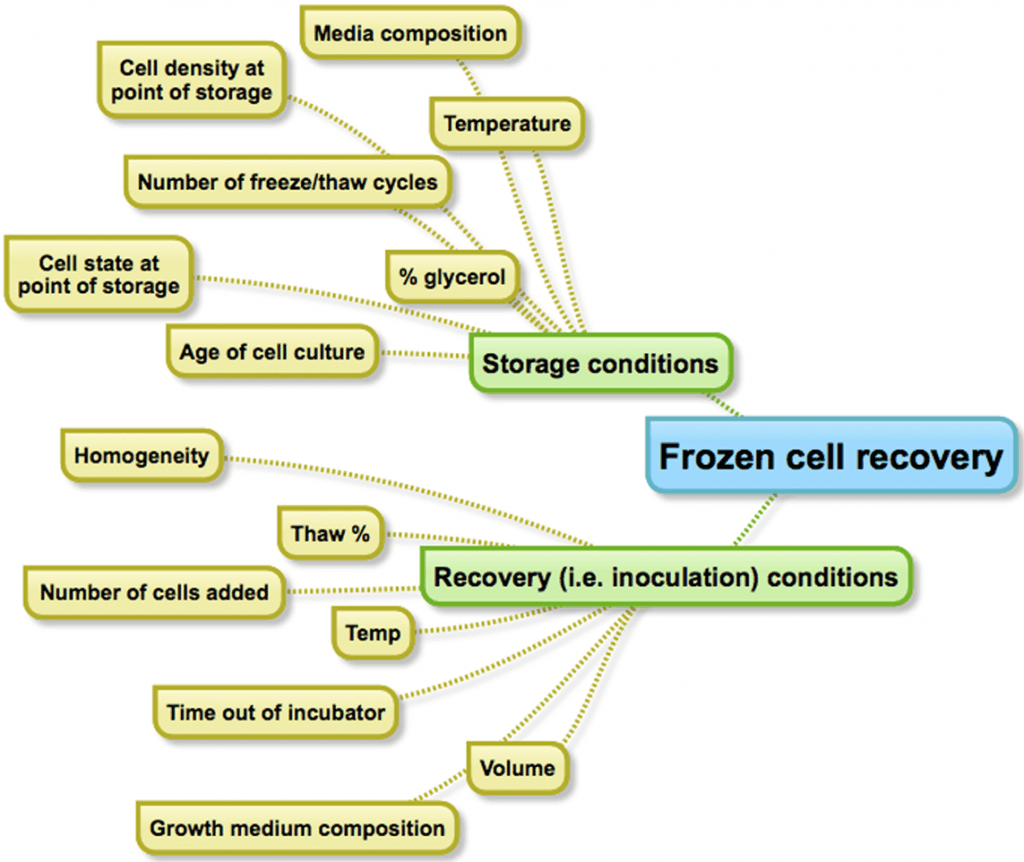

Many variables that can affect an experiment wouldn’t normally be recorded because it’s a laborious process. For example, a simple step such as recovering a frozen cell stock involves the following factors:

Antha aims to automatically capture as many experimental factors as possible, increasing the efficacy of experimental data reporting.

Synthace Takes on Reproducibility Crisis

Founded in 2011 in London, the bioengineering company has attracted £4M from top life science venture capital firms including Sofinnova Partners, SOSventures, Bioeconomy Capital and Rainbow Seed Fund. We interviewed Sean Ward, CTO of Synthace, to learn more about the company’s challenges and expectations.

What have been the biggest challenges so far?

Delivering on Antha represents a massive technical challenge, that has required building a strong working understanding of the entire stack of lab equipment in use today. Additionally, developing a user experience that anticipates the complex experiments of tomorrow, but is also accessible to the biologists of today has required a great deal of thought and user testing. One of the core goals of this closed beta (to be released in July) is to gather community feedback on our interface, and further refine our roadmap of the most important devices to support, and workflows to efficiently handle.

What does the closed-beta Antha OS feature?

The initial workflow it is targeting is construct assembly, where it offers very high efficiency DNA assembly of up to four separate sequences in about 1-2 hours depending on execution hardware speed. Additional workflows will be released through the course of the programme, with community interest partially driving that roadmap.

What about traditional Laboratory Information Management System tools?

Traditional LIMS systems are forensic tools, where you have to import or manually enter data about every action taken. Imagine a word processor where you had to enter into a text field if the printer ran out of ink after you hit print! Antha solves this problem by enabling a rapidly configured workflow description to drive the configuration of the hardware and working practices required to execute the experiment. That includes managing the data outputs and the error tracking throughout, enabling lightweight reporting for manual processes, and automated processes for robot driven steps. It also enables the integration of sensor streams in the unified experiment logs that are produced, enabling forensic trace ability into why experiments may have failed.Additionally, Antha is built for the modern world, where working practices need to be translated between different environments, including manual execution, various desktop automation solutions, and organisation level fully automated foundries. Previous systems were built purely to exist as a silo within a single organisation, and not for the connected internet of biology that is emerging today.

What can we expect in the next months?

Our core business is bioprocess optimisation, and over the next months you will see announcements of our deals with a number of top tier multinationals including big players in the pharmaceutical, agricultural, and chemical industries.Separately, you will also see news about other hardware manufacturers that are starting to support Antha drivers for their equipment, reagent providers that are streamlining consumable management, as well as organisations that will begin to offer remote execution of workflows as a core service for their communities.Please leave your comments or questions below. Thanks to Spencer R. Scott for contributing to this blog post.