Microbial Cell Factories: A Delicious and Glamorous Revolution

Microbes become unlikely heroes in the fight against the global food crisis and environmental challenges in the beauty industry, as highlighted in KAIST's recent paper

Aug 3, 2023

BRGFX (Canva)

In the face of relentless global population growth, a formidable food crisis once again threatens the world. The reasons behind this impending catastrophe are twofold: the crippling impact of abnormal weather patterns intensified by climate change and the breakdown of the global food supply chain due to escalating international conflicts, particularly wars, which exacerbate food shortages and nutritional disparities worldwide. As awareness of environmental issues and sustainability rises, so does the demand for eco-friendly, high-quality food and beauty products. At this critical juncture, microorganisms emerge as potential key players, offering solutions to these seemingly disparate problems.

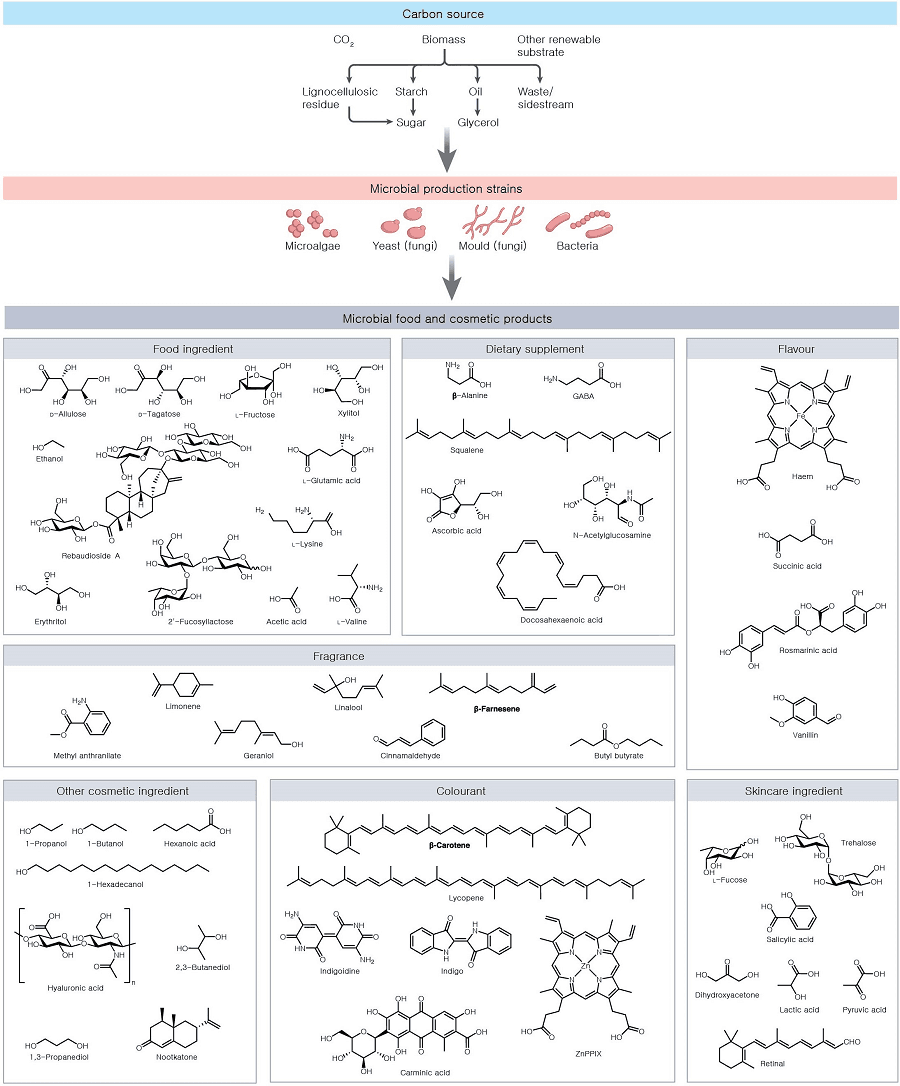

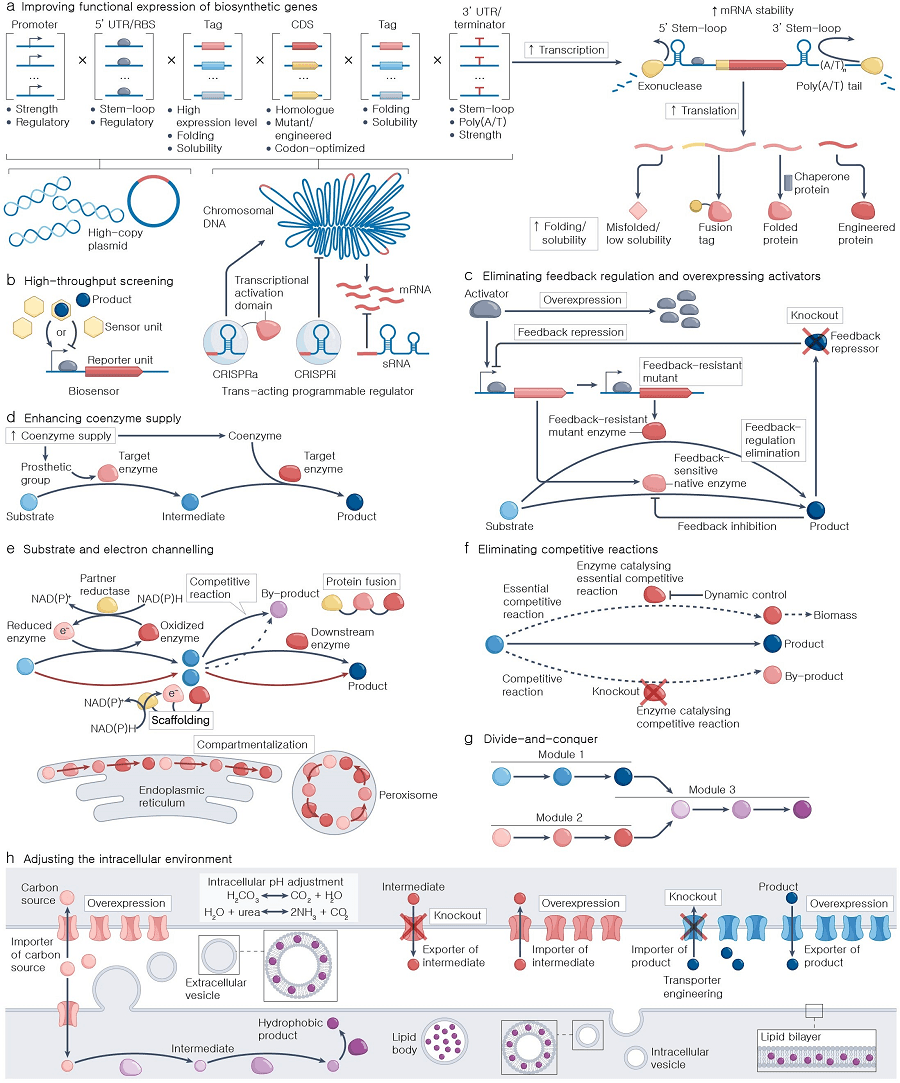

The domain of systems metabolic engineering, founded by Distinguished Professor Sang Yup Lee of Korea Advanced Institute of Science & Technology (KAIST), aims to revolutionize the next-generation bio-industry by effectively developing microbial cell factories, which would replace the existing chemical industry heavily reliant on petroleum. Employing a systemic metabolic engineering strategy, the researchers have created a series of high-performance microbial cell factories capable of producing diverse food and cosmetic compounds. These include natural substances such as heme and zinc protoporphyrin IX compounds, enhancing the flavor and color of synthetic meat, functional natural pigments like lycopene and β-carotene widely used in food and cosmetics, and methyl anthranilate, a grape-derived compound used extensively for imparting grape flavor in food and beverage manufacturing.

In their recent paper for Nature Reviews Bioengineering, the research team extensively covered noteworthy cases of microbial cell factories producing amino acids, proteins, fats and fatty acids, vitamins, flavors, pigments, alcohols, functional compounds, and other additives for various food and cosmetic applications. The paper also organized and presented systems metabolic engineering strategies that can drive the development of industrial microbial cell factories producing a broader range of food and cosmetic compounds in an eco-friendly manner with economic feasibility.

For instance, the researchers demonstrated how microbial fermentation processes can produce proteins and amino acids with high nutritional value from non-edible biomass used as animal feed or fertilizer, thereby contributing to increased food production and stable supply worldwide. Additionally, by advancing viable alternative meat production, reliance on animal protein can be reduced, leading to a decline in greenhouse gas emissions and environmental pollution associated with livestock breeding and fish farming.

Moreover, natural compounds like vanillin or methyl anthranilate, responsible for vanilla or grape flavors in various foods, are currently sourced from plants, resulting in limited production and high costs. Other additives, including calmin, a coloring agent widely used in cosmetics and foods, is extracted from cochineal insects living only in specific cacti, and Hyaluronic acid, which is currently sourced from omega-3 fatty acids found in shark or fish livers, brings ethical and resource-related issues. To address these, microorganisms can offer an eco-friendly and cost-effective alternative for their production.

Professor Kyeong Rok Choi, the first author of the paper, highlighted the progress already made in producing foods like cocoa butter, a fundamental ingredient in chocolate derived from fermented cacao beans, and monosodium glutamate, a seasoning produced through microbial fermentation. “In the future, we will be able to acquire a wider variety of foods and cosmetics even more easily produced in an eco-friendly and sustainable way in our daily lives through microbial cell factories,” he added.

Distinguished Professor Sang Yup Lee remarked that it is the mission of engineers to leverage science and technology for the betterment of the world. He emphasized, "Continuous advancement and active use of systems metabolic engineering will contribute greatly to easing and resolving the problems arising from both the food crisis and the climate change."

This groundbreaking research was conducted as part of the "Development of Protein Production Technology from Inorganic Substances through Control of Microbial Metabolism System Project" led by Research Professor Kyeong Rok Choi, and the "Development of Platform Technologies of Microbial Cell Factories for the Next-generation Biorefineries Project" led by Distinguished Professor Sang Yup Lee, both supported by the Rural Development Administration and the Ministry of Science and ICT, respectively, in their pursuit of innovative solutions for a sustainable future.