Handheld Bioprinter Could Usher Bespoke Tissue Generation for Regenerative Medicine

Jun 14, 2023

Credit: Sheldon Miller, Arvydas Maminishkis, Robert Fariss, and Kapil Bharti, National Eye Institute/NIH

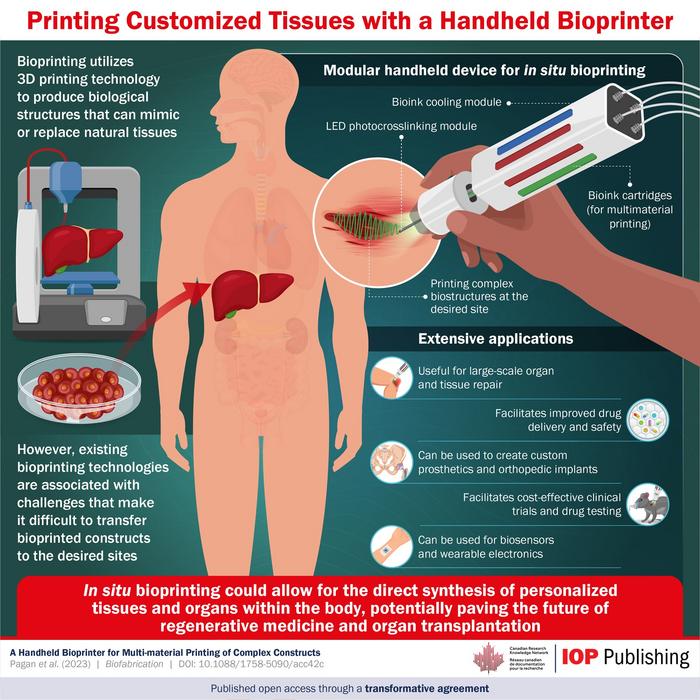

The field of in situ bioprinting, a process that entails 3D printing biocompatible structures directly within the human body, has seen substantial strides in recent times. A team of scientists recently introduced a handheld bioprinter that overcomes the limitations of earlier models, notably the capability to print an array of materials and manage the physical and chemical properties of the printed tissues. This innovation sets the stage for numerous applications in regenerative medicine, drug development and testing, and custom-made orthotics and prosthetics.

Regenerative medicine has come to the fore as a groundbreaking method to replace, repair, or regenerate damaged tissues and organs, thereby dramatically improving patients' lives worldwide. In situ, bioprinting, a derivative of 3D printing technology, represents a significant advance in this field, capable of directly creating tissues and organs within the body. This capability holds immense potential for aiding the repair and regeneration of impaired tissues and organs.

Existing in situ bioprinting technologies, despite their considerable advancements, have certain limitations. Some are only compatible with specific types of bioink, and others are capable of producing only small tissue patches at a time. Besides, these devices are generally complex in design, resulting in high costs and limiting their use.

However, a groundbreaking study recently published in Biofabrication presents a handheld in situ bioprinter featuring a user-friendly modular design capable of printing intricate biocompatible structures. A research team, including Mr. Erik Pagan and Associate Professor Mohsen Akbari from the University of Victoria in Canada, developed the device. Prof. Akbari, discussing the motivation behind the study, said, “Two decades ago, my mother was diagnosed with breast cancer, which eventually led to the removal of her breast. This affected her well-being considerably. It made me realize that a technology like handheld bioprinting could not only help develop personalized implants for breast reconstruction that match the shape and size of the patient’s tissue but also be used to create tumor models for the study of breast cancer biology. Such applications could significantly improve treatment outcomes for affected patients.”

A distinguishing feature of this handheld device is the inclusion of multiple bioink cartridges, independently managed by a pneumatic system. This design allows the device operator to precisely control the printing mixture, thereby simplifying the creation of structures with the desired properties. Furthermore, the device is equipped with a cooling module and a light-emitting diode photocuring module for added control.

“We reported on a modular handheld bioprinter that deposits a variety of bioinks in situ with exquisite control over their physical and chemical properties. Combined stereolithography 3D printing and microfluidic technologies allowed us to develop a novel low-priced handheld bioprinter,” the authors wrote. “The ergonomic design of the handheld bioprinter facilitates the shape-controlled biofabrication of multi-component fibers with different cross-sectional shapes and material compositions. Furthermore, the capabilities of the produced fibers in the local delivery of therapeutic agents was demonstrated by incorporating drug-loaded microcarriers, extending the application of the printed fibers to on-demand, temporal, and dosage-control drug delivery platforms. Also, the versatility of this platform to produce biosensors and wearable electronics was demonstrated via incorporating conductive materials and integrating pH-responsive dyes.”

This versatile in situ bioprinter has multiple potential applications. "In situ bioprinting is suitable for repairing large defects caused by trauma, surgery, or cancer, which requires large-scale tissue constructs. In the long term, this technology can eliminate the need for organ donors while also lowering the risks associated with transplantation, allowing patients to enjoy longer and healthier lives," says Prof. Akbari.

The bioprinter could also be utilized to create drug delivery systems. Operators can design scaffolds or structures to release precise amounts of drugs and cells at designated locations within the body. This precision would increase drug effectiveness, reduce associated side effects, and enhance safety. Furthermore, this technology could expedite the discovery of new drugs by enabling scientists to devise more accurate drug-testing models.

The bioprinter's portability could lead to the development of tailor-made prosthetics and orthopedic implants, enabling physicians to accurately match a patient’s tissue anatomy, thereby improving the functionality and aesthetics of the bioprinted construct.

The outcomes of this study could greatly assist researchers and physicians in expanding the field of regenerative medicine and facilitate collaborative research to advance this technology further. Acknowledging this potential, Prof. Akbari and his team made this study available through a transformative agreement between IOP Publishing and the Canadian Research Knowledge Network. This arrangement allows authors to publish their work in over 70 IOP Publishing journals without incurring costs, providing immediate and free access to everyone. Prof. Akbari concludes, "By publishing under a transformative agreement, we are promoting a more sustainable and equitable scholarly publishing model that benefits the entire research community. This can address long-standing challenges of access and affordability in academic publishing while also promoting the growth of scientific knowledge.”