DARPA Taps Ginkgo Bioworks for $18M Project in Therapeutic Protein Manufacturing

Under a 4-year contract with DARPA, Ginkgo Bioworks aims to overcome the limitations of traditional manufacturing methods by enabling rapid, on-demand production of therapeutic proteins

Jul 19, 2023

Alacatr (Canva)

Ginkgo Bioworks (NYSE: DNA), a pioneering firm in cell programming and biosecurity, was selected by the Defense Advanced Research Projects Agency (DARPA) for a contract worth up to $18 million. The 4-year deal was awarded as part of DARPA's Reimagining Protein Manufacturing (RPM) project, with Ginkgo promising groundbreaking developments in on-demand protein manufacturing through Cell-Free Protein Synthesis (CFPS).

Ginkgo, renowned for its revolutionary platform for cell programming, aims to spearhead innovation in protein manufacturing, enabling the swift, high-yield, and distributed production of human therapeutic proteins vital to national security objectives. In a high-profile collaboration, Ginkgo will work closely with representatives from Imperial College London, Nature’s Toolbox, Inc., and Michael Feldhaus, a seasoned consultant and former Executive VP of Antibody Discovery at Adimab.

Jason Kelly, CEO and co-founder of Ginkgo Bioworks, shared his thoughts on the critical issue facing pharmaceutical supply chains and the transformative potential of distributed manufacturing. "There is growing recognition that pharmaceutical supply chains are at risk. One way to meet this challenge is distributed manufacturing at the point of care,” said Kelly. He envisions a future where drugs, particularly complex biologics, could be produced locally or on demand in a widely distributed fashion. “We’re very excited to be working with DARPA to make that future a reality,” he added.

The focus of this novel project is therapeutic proteins with "post-translational modifications," like antibodies, cytokines, and clotting factors, which are particularly important for DARPA and the broader marketplace. Such proteins form a significant part of the top-selling drugs treating cancer and autoimmune diseases. Through this initiative, Ginkgo aims to revolutionize traditional cell-based methods with more efficient cell-free methods.

While traditional methods can be effective, they are also often time-consuming, taking months to engineer bespoke cellular organisms and produce the desired therapeutic protein. With the advent of Cell-Free Protein Synthesis (CFPS), however, this process could be significantly faster and more flexible, although improvements are needed to make CFPS as efficient as traditional therapeutic protein production.

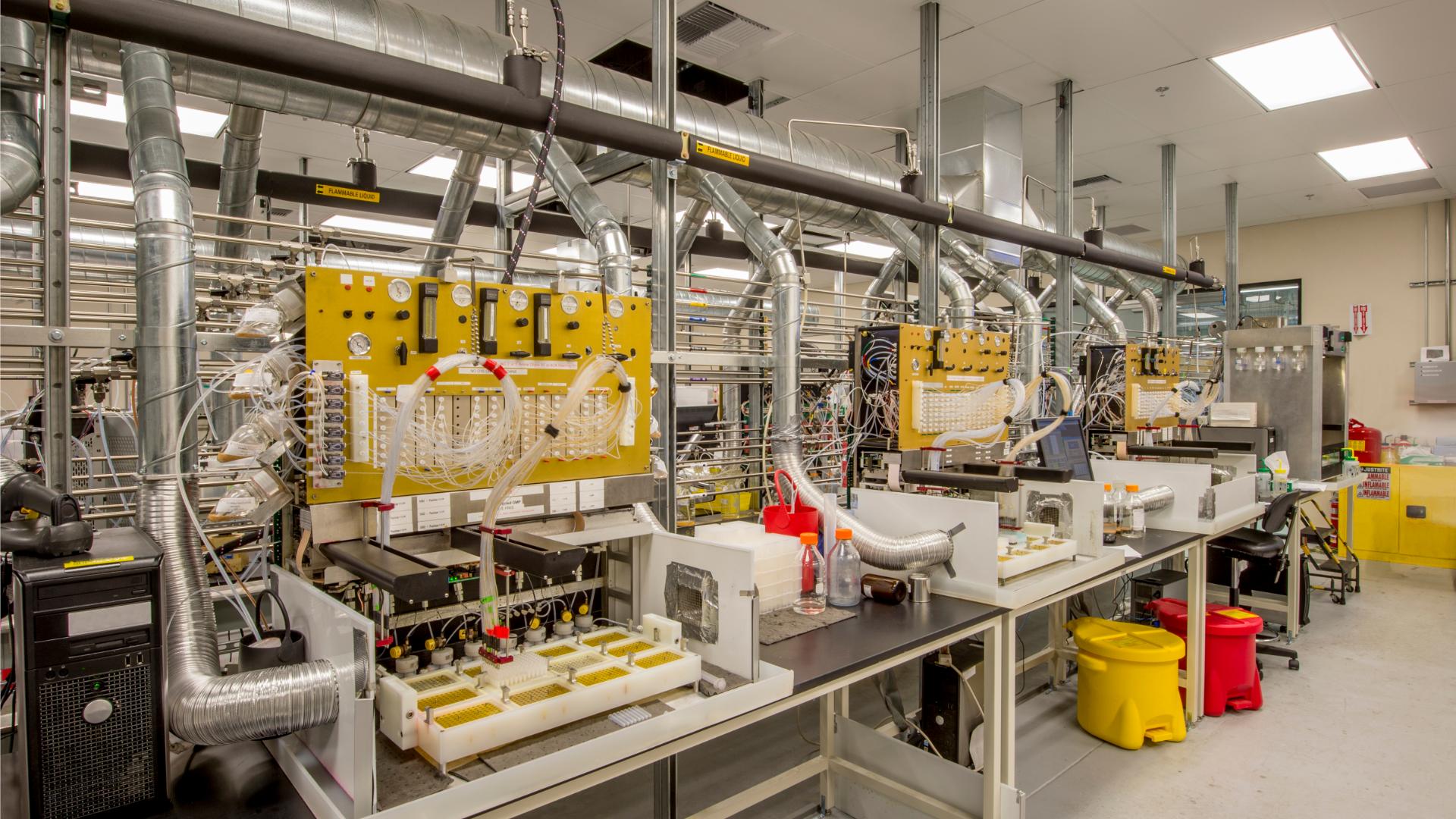

As part of this endeavor, Ginkgo plans to harness its high-throughput, automated Foundry and its proprietary genetic data Codebase. This includes a remarkable portfolio of over one billion proprietary gene sequences. Ginkgo’s synthetic biology platform, combined with its robust expertise in iterative Design–Build–Test–Learn-driven biological engineering, will facilitate rapid prototyping, optimization, and development of proteins, enzymes, metabolic pathways, and whole organisms under commercial-scale manufacturing conditions. The goal is to create production methods in line with Good Manufacturing Practices, thereby facilitating adoption by the pharmaceutical industry.